Vacuum Atmosphere Furnace – TT-VAF-288-1200

TT-VAF-288-1200 is a 1200°C box-type resistance furnace designed to create a high-temperature heat treatment environment under vacuum or controlled atmosphere conditions. It is ideal for use in industrial laboratories, including those at universities, research institutes, manufacturing facilities, and private organizations. This furnace supports advanced material processing in areas such as metals, ceramics, nanomaterials, and semiconductors.

| Model No. | TT-VAF-288-1200 |

| Inner Dimension (WxDxH MM) | 600x800x600 |

| Continuous Temperature | 1100℃ |

| Max Temperature | 1200°C |

| Voltage | 380V/7.5kw |

| Heating Element | High Quality Alloy Resistance Wire(HRE) |

| Temperature Precision | ±1°C |

| Thermocouple | N type |

Vacuum Atmosphere Furnace – TT-VAF-288-1200 Features

Furnace Shell

- Constructed from Q235 low-carbon steel with an electrostatically resistant, anti-corrosive surface.

- Durable metal tank design ensures a low exterior temperature.

- Side-opening furnace door with a flange-type seal and manual screw compression for easy operation.

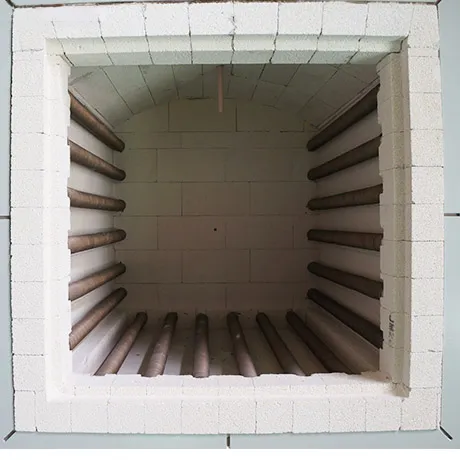

Refractory Material

- Multi-layer insulation composed of lightweight alumina ceramic fiber and high-grade insulation boards. The design is asbestos-free, offering low heat loss and reduced energy consumption.

Heating System

- Equipped with high-quality HRE spiral resistance wire heating elements, securely embedded into the furnace lining. Delivers radiant heat throughout the chamber for energy-efficient, long-lasting performance.

- Three-sided heating (left, right, and bottom) ensures excellent temperature uniformity.

- A silicon carbide base plate protects the bottom heating elements, offering high mechanical strength, efficient thermal conductivity, and stable horizontal load support.

Temperature Control Panel

- PID temperature controller with SSR/SCR output for precise thermal regulation.

- Uses a standard N-type nickel-chromium-silicon thermocouple, with a temperature range of 0–1300°C and extended service life.

Program Controller

- Designed for complex thermal processing.

- User-friendly interface with flexible programming options.

- Supports up to 30 programmable segments in a single profile.

- Built-in over-temperature and system fault alarms with automatic safety shutdown.

Vacuum Atmosphere Function

- The furnace chamber includes adjustable inlet and outlet ports for introducing protective gases.

- Compatible with various vacuum pumps to achieve vacuum levels ranging from 500 Pa to 0.06 Pa. A digital vacuum gauge provides real-time vacuum readings.

- Optional gas control unit available, supporting 1 to 3 adjustable float flowmeters for precise gas flow management.

|

Model |

TT-VAF-3-1200 |

TT-VAF-6-1200 |

TT-VAF-8-1200 |

TT-VAF-12-1200 |

TT-VAF-18-1200 |

TT-VAF-30-1200 |

|

Chamber Size (W xD xH)mm |

150 x150x150 |

180x230x150 |

200x300x120 |

200 x300x200 |

250 x300x250 |

300 x500x200 |

|

Rated Temperature |

1200℃ |

|||||

|

Work Temperature |

1100℃ |

|||||

|

Voltage |

220V/2.5KW (110V is also available) |

220V/3KW (110V is also available) |

220V/3KW (110V is also available) |

220V/4KW (110V is also available) |

220V/6KW (110V is also available) |

220V/7.5KW (110V is also available) |

|

Heating Element |

HRE Alloy Resistance Wire |

|||||

|

Chamber Materials |

Polycrystalline inorganic alumina ceramic fiber material made by wet vacuum filtration methord |

|||||

|

Temp control Accracy |

±1℃ |

|||||

|

Thermcouple |

N Type thermcouple |

|||||

|

Temperature Controller |

Intelligent microcomputer PID temperature control instrument, SCR/SSR control, PID parameter self-tuning function .Programmable 4 groups program curves with each program curve with 8 segments totally 32 segments for program heating, program heat preservation, program cooling |

|||||

|

Heating Rate |

1-25℃/min can be adjustable |

|||||

|

Furnace Structure |

Furnace temperature control integrated structure |

|||||

|

Equipment Protection |

Modular control with sound and light alarm signal sending out for over temperature and thermocouple broken in the working process, and the protection action will be completed automatically |

|||||

|

Safety Protection |

The equipment is equipped with a circuit breaker, which will automatically pop open in case of short circuit leakage, which can protect the safety of equipment and operators |

|||||

|

Furnace Shell |

High-quality cold-rolled steel plate with CNC machine tool processing, then it will have the process of welding, grinding, polishing, phosphating, pickling, surface electrostatic spraying plastic powder |

|||||

|

Quality Certificate |

ISO9001 CE SGS TUV |

|||||

|

Standard Device |

1、Furnace Main Body : 1 set 2、Temperature Controller : 1 pc 3、Power Line : 3 meters 4、Thermcouple : 1 pc 5、Operation manual ; 1 pc 6 Crucible Tong ; 1 pc 7、High Temperature Gloves : 1 pair |

|||||

|

Optional Accessories |

1、Optional with Rotary Vacuum Pump (Vacuum Degree Level ≤500pa) 2、Optional digital vacuum gauge (1.0×105-1.0×10-1pa) 3、Optional with gas float meter (Float flow rage 1-10L/min) |

|||||