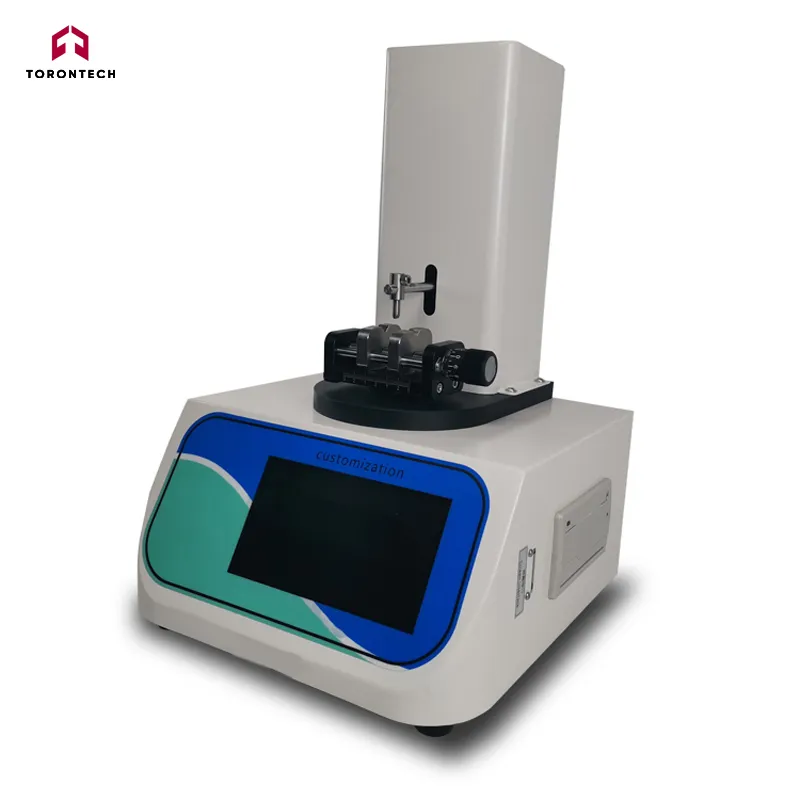

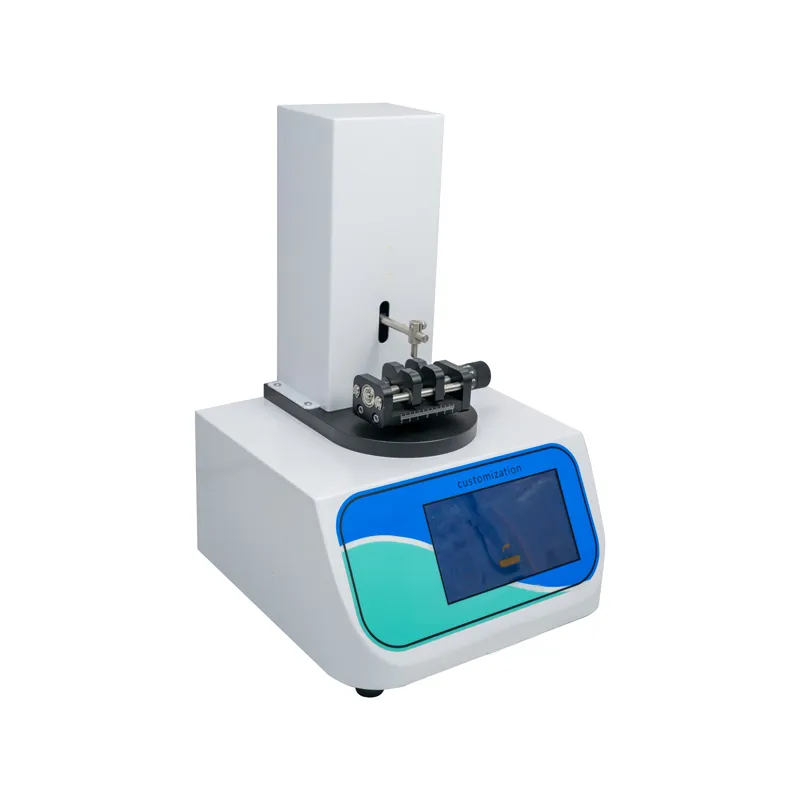

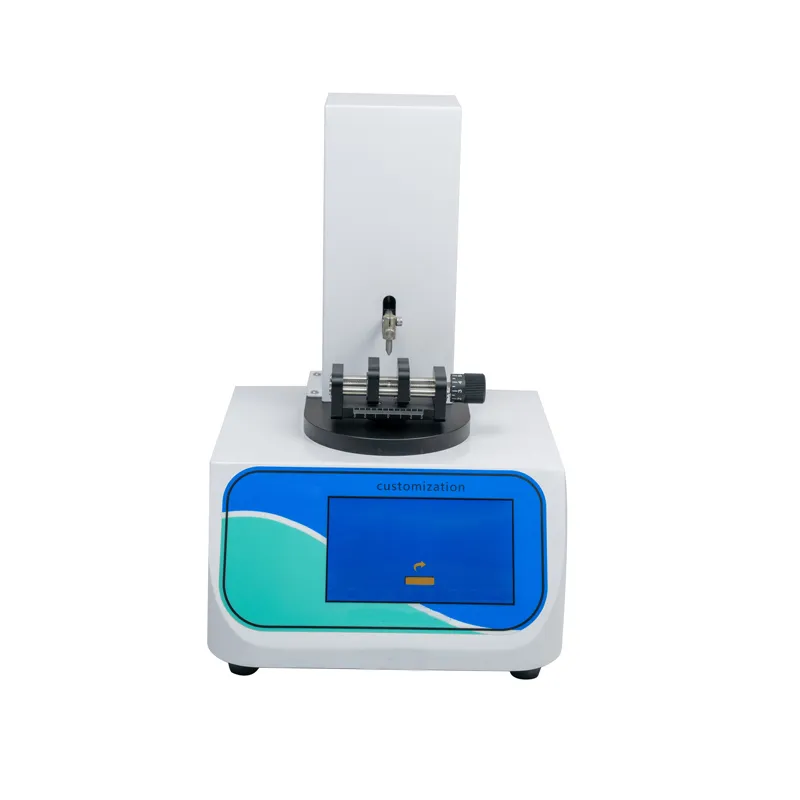

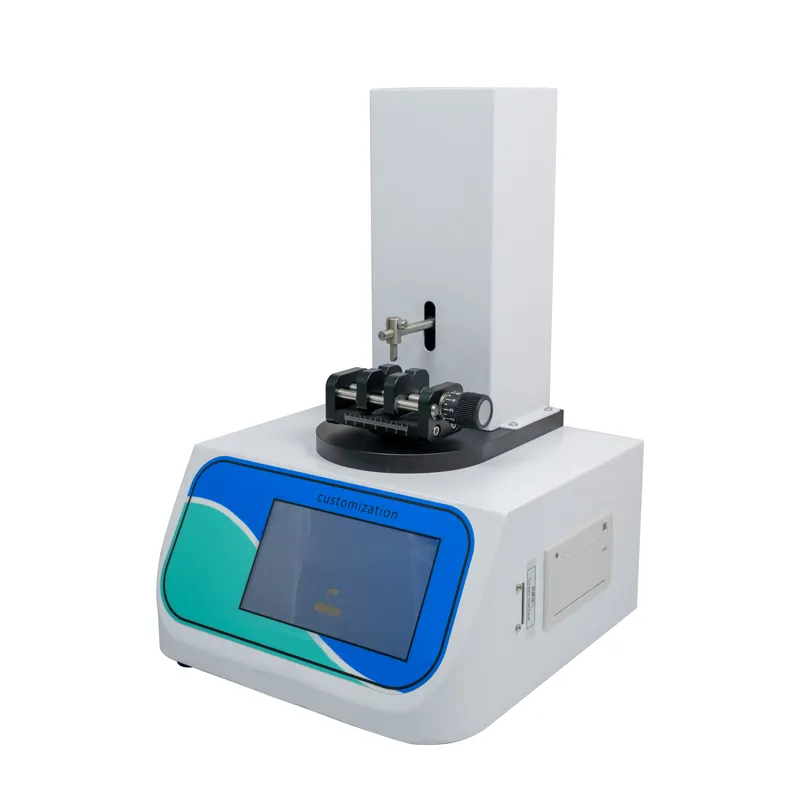

Medical Needle Tubing Stiffness Tester

ISO 9626

Medical Needle Tubing Stiffness Tester – ToronMed-MNTST01 is designed to measure the stiffness and rigidity of stainless-steel needle tubing used in intradermal, subcutaneous, intramuscular, and intravenous disposable injection needles, as well as prefilled syringe needles and infusion needles. By simulating bending resistance, the tester ensures that medical needles meet strict international safety and quality standards.

This tester is widely used in medical device manufacturing, R&D labs, pharmaceutical packaging validation, and quality control environments.

Test Principle

The Medical Needle Tubing Stiffness Tester applies a controlled bending force to the stainless-steel needle sample. A specialized rigidity sensor records the stiffness value, providing precise and repeatable results. The test replicates real-world performance to confirm that tubing resists deformation during clinical use.

Applications

- Basic Applications

- Disposable sterile injection needles

- Prefilled syringe needles

- Extended Applications

- Infusion needles

- Blood sampling needles

- Dental needles

- Biopsy needles

- Other stainless-steel medical tubing requiring stiffness evaluation

Standards Compliance

The ToronMed-MNTST01 Medical Needle Tubing Stiffness Tester is designed in accordance with:

- ISO 9626 – Stainless steel needle tubing for manufacture of medical devices

Standard Configuration

- Main instrument unit

- Touchscreen interface

- Micro printer

- Span gauge (ISO 9626-compliant)

- Test fixture

Why Choose Medical Needle Tubing Stiffness Tester – ToronMed-MNTST01

The Medical Needle Tubing Stiffness Tester – ToronMed-MNTST01 ensures precision, compliance, and reliability for evaluating the stiffness of medical needle tubing. With its advanced automation, multi-wall compatibility, GMP-ready data management, and intelligent safety features, it is the trusted choice of medical device manufacturers, inspection authorities, and R&D labs worldwide. This tester helps guarantee that medical needles deliver consistent performance and patient safety.

Key Features

- 7-Inch Color Touchscreen

Real-time display of curves, results, and intelligent data analysis. - High-Precision Control System

Advanced displacement and force sensors ensure highly accurate test results. - Automated Testing Process

Automatic calibration, judgment of qualification, and experiment termination for simplified operation. - Stepless Span Adjustment

Eliminates the need for manual span block replacement. - Broad Compatibility

Supports regular wall, thin wall, extra-thin wall, and ultra-thin wall needle tubing. - Large Data Storage

Stores more than 100,000 test records, with built-in micro printer and USB interface for data export. - Data Security (Optional)

GMP-compliant software with user management, authority control, and audit trail capabilities. - Safety Protection

Built-in over-range shutdown prevents sensor overload.

| Specification | Value |

|---|---|

| Deflection Range | 0–5 mm |

| Deflection Accuracy | ±0.01 mm |

| Bending Force Range | 1–80 N |

| Force Accuracy | ±0.1 N |

| Needle Span | 0–60 mm |

| Span Accuracy | ±0.1 mm |

| Needle Tubing Size | 0.18–3.4 mm (regular, thin, extra-thin, ultra-thin walls) |

| Loading Speed | 0–10 mm/min (v=1 mm/min standard) |

| Speed Accuracy | ±0.1 mm/min |

| Dimensions | 300 × 300 × 455 mm |

| Net Weight | 30 kg |

| Voltage | AC 220V / 50Hz (110V is also available) |