Desk Sputter Coater- DSR1

The Desk Sputter Coater- DSR1 is a compact coating system capable of applying thin films of noble metals like gold (Au), palladium (Pd), platinum (Pt), and gold/palladium (Au/Pd) onto non-conductive or poorly conductive specimens. It excels at producing uniform thin films with fine-grain sizes in a quick cycle time.

The resulting thin film is ideal for scanning electron microscopy (SEM) analysis. The Desk Magnetron Coater is a highly efficient tool that ensures consistent and reliably reproducible results within a fully automated system. Its ergonomic design and compact footprint make it user-friendly and easy to operate.

This Desk Sputter Coater- DSR1 system serves as a sample preparation solution for scanning electron microscopy (SEM) and is equipped with a rotary pump to attain a vacuum level of less than 50 millitorr. This vacuum range is ideal for sputter coating noble metals.

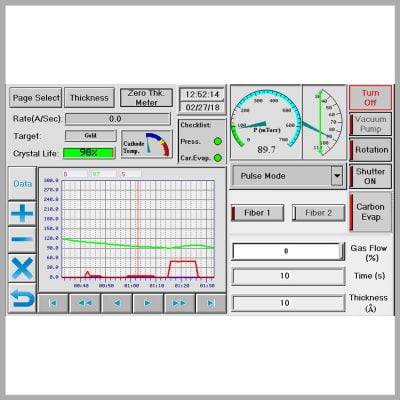

Touch Screen Control with Colorful Display

The desk sputter coater features a 7-inch color touchscreen interface with full automatic control and user-friendly data input, making it accessible even for inexperienced users. Users can easily operate the system through the touchscreen, where vacuum levels, current, and deposition information can be viewed as digital data or displayed as curves. Additionally, the system can store information on the last 300 coatings, which can be accessed in the history page for reference.

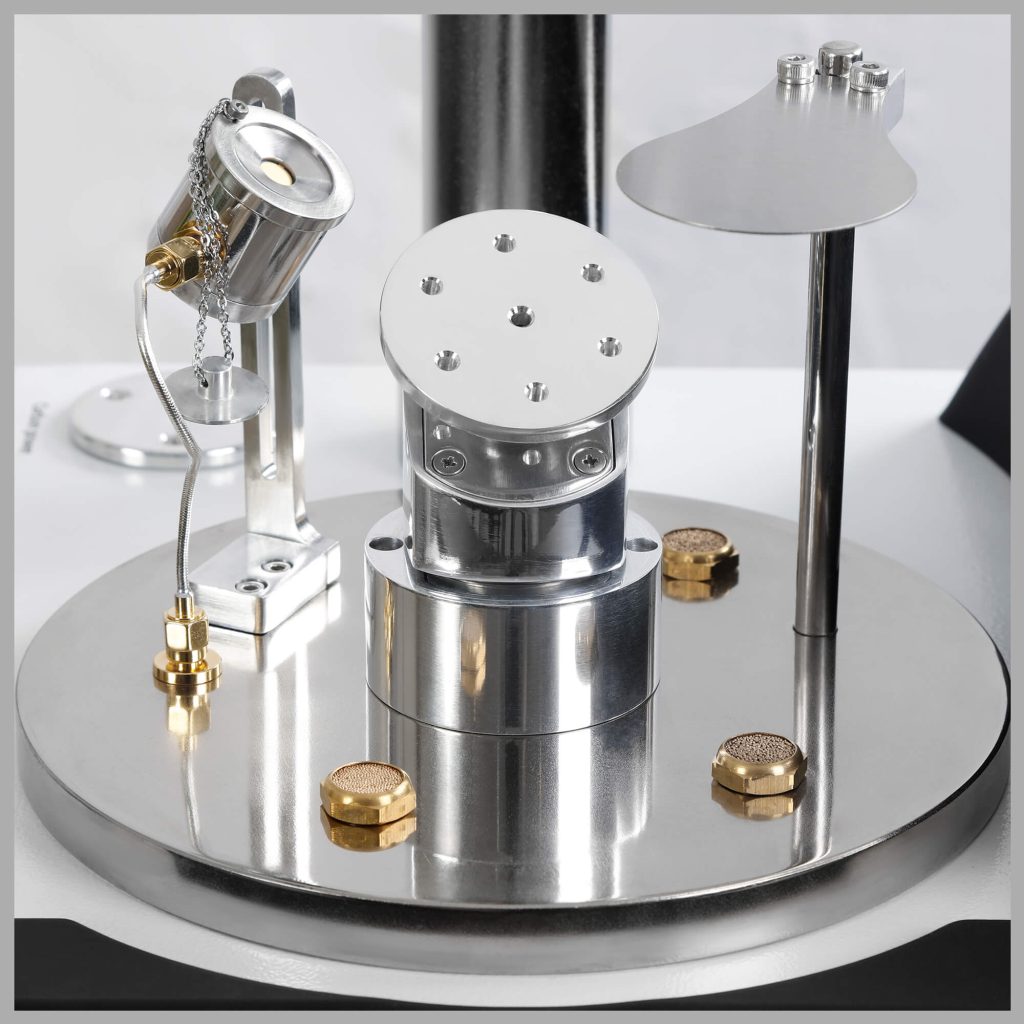

Sample Holder

The DSR1 offers various sample stage configurations to suit user requirements. The standard sample stage is rotatable and comes with adjustable height and angle settings, providing easy customization.

For achieving uniform coating on porous specimens, the rotary planetary sample stage is a recommended choice.

These specifications provide detailed information about the product's size, weight, power requirements, and key features.

Options and Accessories

These are the optional accessories and components that can be used with the system.