Desk Carbon Coater - DCR

Desk Carbon Coater - DCR is a compact carbon fiber coating system designed for sample preparation for use in scanning electron microscopy (SEM), transmission electron microscopy (TEM), and X-ray analysis (EDX) applications.

DCR Options and Accessories

The Carbon Coating System offers the following options and accessories:

Pulsed Carbon Fiber Evaporation

The desk vacuum carbon coating system, known as DCR, is capable of performing pulsed carbon fiber evaporation. Short pulses enable more precise deposition and significantly reduce the amount of debris typically associated with conventional carbon deposition methods.

Touch Screen Control with Colorful Display

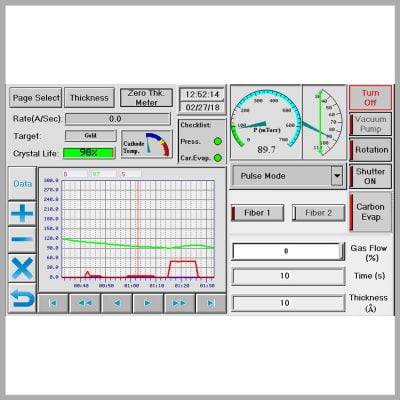

The desk carbon coater features a 7-inch color touchscreen interface, offering full automatic control and data input capabilities that are user-friendly, even for inexperienced users. Users can easily operate the system through this touchscreen. The vacuum level, current, and deposition information can be monitored as digital data or displayed as curves on the touchscreen. Additionally, the system stores information on the last 300 coatings, which can be accessed in the history page for reference.

Sample Holder

The DCR can be customized with various sample stage configurations to meet the specific needs of users. These sample stages are designed to be rotatable with adjustable height, allowing for easy customization. The rotary planetary sample stage is particularly well-suited for achieving uniform coating on porous specimens and is recommended for such applications.